Forks are FIBC Killers

I have often noticed complaints from customers that the Bag Handle broke. It’s important to understand that the Bag is holding a TON of weight ( Pun Intended ). When the Forklift stops, breaks or moves, there is movement. Loops get abraded with the sharp edges on the fork, eventually forming cuts and breaking.

How do we solve this issue?

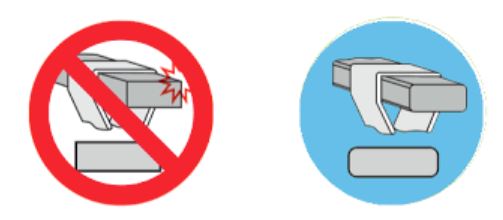

So as per New FIBC Safe Handling Guidelines and Research has found that the Forks of the Forklift need to be Curved or Angled (Adding an image here would help). This reduces the abrasion by 80% as compared to the sharp edges.

In summary, improper use of forklift forks can cause significant damage to FIBC bags, with complaints from customers about broken bag handles being common. FIBC bags are designed to carry a ton of weight, and movement from the forklift can cause abrasion and eventually lead to cuts and breaking of the bag loops. The solution to this problem is to use forklift forks that are curved or angled, which research has shown can reduce abrasion by up to 80% compared to sharp edges. By implementing this solution, companies can help ensure that FIBC bags are handled safely and without damage, leading to greater customer satisfaction and fewer complaints.

0 Comments