Q bags / Baffle Bags

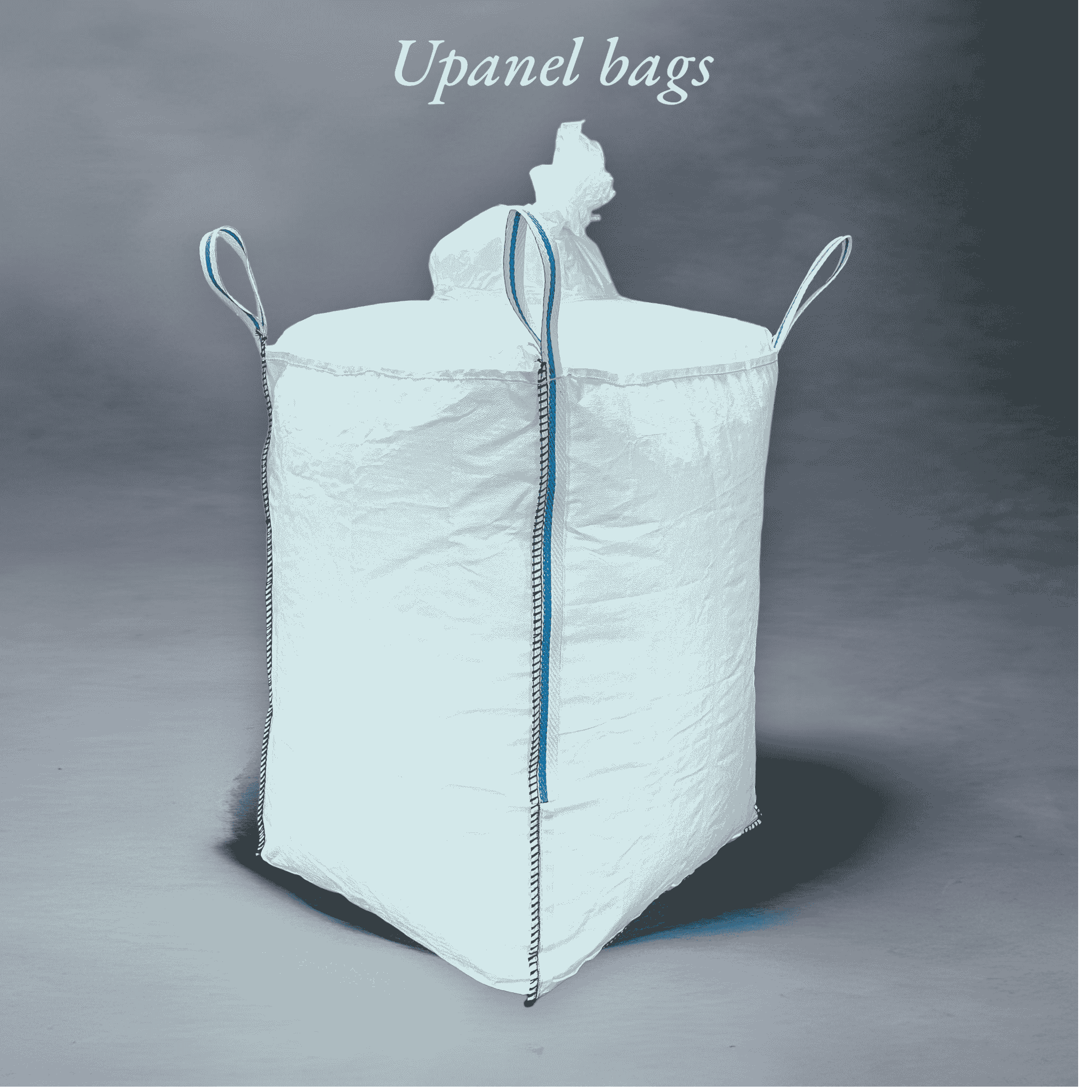

FIBC bags are customized for various industries to pack solid dry bulk materials. Common options include U-panel, Circular and 4-panel bags, but these can lose their square shape when filled to capacity, causing issues with transportation. Baffle bags were introduced to solve this problem by stitching extra panels or strings to each corner of the bag, allowing it to retain its shape. These bags, also called FIBC Q bags, are best suited for dry, free-flowing products like sand, chemicals, and agricultural products. Benefits of using baffle bags include extra storage space, efficient use of space, cost-effectiveness, stackability, stability, and preservation of contents. They are also designed to prevent spilling and leakage during transportation.

Benefits of Q Bag ( Baffle Bag )

- Build extra storage space, by at least 30%

- Retain the square packaging of the bags, preventing them from bulging unpleasantly at the sides when filled

- Provide for optimum utilisation of space, as the contents fill all the corners of the bag, giving it a neat, compact look. You can easily pack more material within a limited space.

- Cost-efficient solutions for the storage and transportation of dry, flowing products

- Easily stackable, which saves space in the warehouse

- Firm, steady, and strong. These features render the baffle bulk bags stable.

- Robust, reinforced structural design allows safe handling.

- Effectively preserve the quality, flavour, and composition of the food and other contents.

- Specially designed to prevent spilling and leakage during loading, transportation, and unloading.